Sealcoating in Central Ohio & Beyond

Looking for help with sealcoating? You have come to the right place! We work with residential and commercial customers throughout the state of Ohio! Whether you need your driveway sealed, or you are in need of help with a commercial parking lot or highway, we have the team and the equipment to get the job done.

Our Sealcoating Services

Sealcoating isn’t just maintenance—it’s a game-changer for your asphalt. We offer a variety of sealcoating services to meet the needs of our Ohio community! No project is too big or too small for us. Seal it today, and thank yourself later!

Residential & Commercial

We work with paved spaces large and small and nothing is too large for our team and our equipment. We provide sealcoating for parking lots for malls, grocery stores, hospitals, schools, and other large spaces. Our team works seamlessly to coordinate these projects, and are highly skilled in handling large projects from start to finish!

Driveways

We work with homeowners in need of driveway sealing to seal up imperfections caused by routine wear and tear. Freezing and thawing of asphalt in colder climates like Ohio can cause asphalt to crack, making sealcoating a great way to extend the live of your driveway.

Parking Lots & Garages

Why seal your parking garage or lot? It’s the secret to protecting your investment and doubling its lifespan! Think of sealcoating as the ultimate shield against wear and tear, keeping your asphalt looking great and performing even better. When asphalt is first installed, it’s rich with oils, but over time, exposure to the elements—like UV rays and oxidation—causes it to dry out, weaken, and crack. Sealcoating is your defense against this aging process.

Roads & Highways

Roads & Highways often see high levels of wear, tear, and contamination that can cause asphalt to degrade even faster. Construction projects within roadways can make this deterioration even faster! Routine sealcoating can help extend the life of the pavement for as long as possible, saving cities & towns in significant repaving expense.

Why Work with Allseal Sealcoating?

We offer a variety of sealcoating, asphalt, driveway, and road striping services to meet the needs of commercial property owners, homeowners, cities, and towns. Whether you're looking to have your driveway sealed, or are looking to have a hospital parking lot striped, we've got the equipment and the crew to meet your needs! We serve all of Central Ohio and throughout the state.

Satisfaction Guaranteed

We make sure that every job gets done properly, and your satisfaction is at the top of our priority list.

20+ Years of Experience

We have learned a LOT over the years and are able to bring all of the skills and techniques we have to your next project.

Highly Trained Staff

Our staff are the best of the best and we work as a team to get your project completed as quickly and as beautifully as possible. We pay attention to the details and can coordinate large jobs because of our amazing team!

Google Verified

We love our clients and the work that we do. Make sure that you check out some of our Google Reviews to see what other customers had to say about our work!

Ohio Local

We are based right outside of Columbus, Ohio and are proud to be a locally owned and operated business. You aren't hiring a big box contractor - We are members of the community and are proud to serve you!

Proudly Serving Columbus and all of Ohio

Wondering if we offer sealcoating services in your area? We are local to London, Ohio in Greater Columbus and serve all of the state of Ohio. We frequently service the below list of cities and towns nearby, but if you don't see your town don't worry! Feel free to check out our Full Service Area, or give us a call and we're happy to let you know if we can travel to you!

- West Jefferson, Ohio

- London, Ohio

- Mount Sterling, Ohio

- Plain City, Ohio

- Marysville, Ohio

- Milford Center, Ohio

- Commercial Point, Ohio

- Jeffersonville, Ohio

- Columbus, Ohio

- Hilliard, Ohio

- Dublin, Ohio

- Upper Arlington, Ohio

- Grove City, Ohio

- Galloway, Ohio

- Grandview Heights, Ohio

- Mechanicsburg, Ohio

What are the Benefits of Sealcoating?

Prevents Cracking

Sealcoating helps shield your pavement from the sun, which can dry out and crack your pavement.

Seals Against Moisture

The Ohio freeze-thaw cycle can do significant damage to your pavement. Sealcoating helps prevent moisture from getting in!

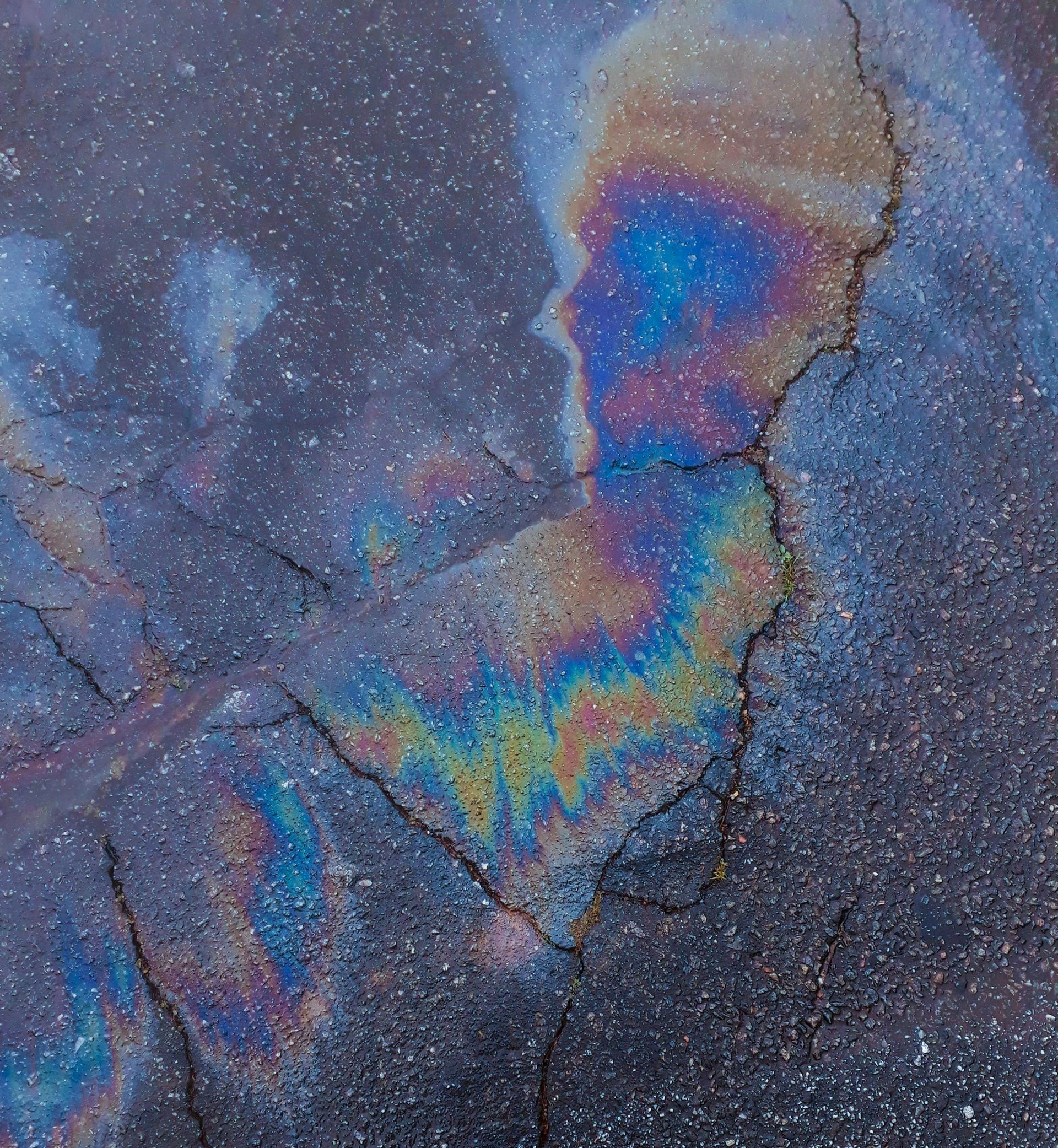

Resists Gas & Oils

Sealcoating helps shield your pavement from the sun, which can dry out and crack your pavement.

Enhance Curb Appeal

Sealcoating beautifies your pavement and brings it that like-new sheen.. without the price!

Got Sealcoating Questions? We've Got Answers.

What are the benefits of sealcoating?

- Shields asphalt from UV rays, chemicals, and oxidation.

- Prevents cracking and prolongs the pavement’s lifespan.

- Protects against water, snow, and ice damage.

- Enhances curb appeal and makes a professional first impression.

- Boosts property value while cutting down on future repair costs.

We are always happy to chat with you more about your project and pavement. Give us a call and we're happy to answer questions!

How frequently do you recommend having a driveway or parking lot sealcoated?

For the best results, asphalt surfaces should be sealcoated every 2 to 3 years . High-traffic areas, such as commercial parking lots and roadways, may require more frequent maintenance. Regular sealcoating extends the lifespan of your pavement and keeps it looking fresh and professional. Looking for an estimate on sealcoating? Give us a call!

Is sealcoating meant to fill in cracks and potholes?

Sealcoating is a protective layer, not a crack filler. Before sealcoating, we recommend repairing any cracks or potholes to ensure a smooth and long-lasting finish. Our team can provide crack repair and asphalt patching services before applying the sealcoat for the best results.

How long do you recommend waiting after sealcoat is applied to use my driveway?

The drying time depends on temperature, humidity, and sun exposure. Typically, sealcoating dries within 4 to 8 hours and can be opened ONLY to foot traffic. We recommend waiting at least 24 to 48 hours before driving or parking on the surface. If you use it sooner, you risk ruining the sealcoat.

What’s the best time of year to schedule sealcoating in Central Ohio?

Spring through early fall is the ideal time for sealcoating, as temperatures above 50°F allow our sealant to cure properly. We closely monitor weather conditions to ensure the best application and long-term durability, and give you our best recommendations on how long to wait before using the surface based on the temperature.

Does sealcoating make asphalt slippery?

No! Our sealcoating process includes a slip-resistant additive to maintain traction, making it safe for both pedestrians and vehicles. Properly applied sealcoating enhances durability without compromising safety.

How should I prepare for a sealcoating service?

To prepare for your sealcoating service with us:

- Clear the area of vehicles, debris, and loose dirt.

- Mark any areas that need special attention, such as cracks or potholes.

- Avoid using sprinklers or washing the pavement 24 hours before service.

Our team will handle the final cleaning and prep before applying the sealcoat!

How does Ohio’s weather affect my asphalt?

Ohio’s freeze-thaw cycles cause asphalt to expand and contract, leading to cracks and surface damage. Sealcoating acts as a waterproof barrier, protecting your pavement from moisture penetration and extending its lifespan, even through harsh winter conditions.

Is sealcoating necessary for both residential and commercial properties?

Absolutely! Whether you have a driveway, parking lot, or private roadway, sealcoating helps preserve the surface, enhances curb appeal, and protects your investment. We work with homeowners, businesses, hospitals, schools, and municipalities throughout Central Ohio.

How do I get a free quote for sealcoating services?

Getting a quote is easy! Simply give us a call or fill out our online form, and we’ll provide a customized estimate based on the size and condition of your asphalt. We’re happy to answer any questions and schedule your service at a time that works well for you!

Do you offer sealcoating discounts?

We offer a group discount for completing multiple projects within the same neighborhood or within very close proximity! These jobs must be paid and completed in order to receive the discount. This can significantly benefit business owners, developers, and municipalities looking to have multiple jobs completed! Feel free to Contact Us if this is something that you are interested in, and we are happy to give you a free estimate for the work you are looking to have done!

How long should I wait for my sealcoating to dry before using my driveway?

Drying time may vary from day to day, so we always ask that you use your best judgement. IF IT LOOKS WET, IT IS WET! You may walk on your driveway as soon as it is dry to the touch. Please keep cars off of the sealer for an additional 48 hours. Heavily shaded areas may take even longer. Also allow for longer drying times during increased humidity and extreme temperatures.

I have sprinklers. Should I shut them off before getting sealcoating on my driveway?

Please make sure that your sprinkler system is turned OFF and remains off for an additional 48 hours following sealing. This will wash away the sealer.

I see what look like tire marks in my new sealcoating! What should I do?

During extreme temperatures and periods of increased humidity you will likely experience what appear to be tire marked in your freshly sealed asphalt. This is completely normal and to be expected. The marking WILL subside as temperatures decrease and cooler weather approaches.

The edge of my sealcoated driveway looks different from the rest. Is that normal?

You may notice where we had to hand edge such things as your house, fence, or walkways. This is necessary to avoid getting any sealer on your property.

I had cracks repaired under my sealcoating that sunk in. Is that normal?

The material used for hot crack sealing is a commercial grade hot pour rubberized crack sealer. Due to variations in crack sizes, this crack seal may NOT be flush with the rest of the driveway. This should not raise concern - The cracks are still protected.

What is your service area for sealcoating?

We offer sealcoating for homes and businesses throughout Greater Columbus, Central Ohio, and all of Ohio State. You can see more details on our Service Area page.

We do our best to answer some of the most common questions we hear about sealcoating and our services, but if you have another question never hesitate to give us a call. We're always happy to chat with you about your project, get you a free quote, and answer any questions that you have!